GENERAL - FITTING

🔧 General Overview – Butt-Welding Fittings

✅ Definition

Butt-welding fittings are pipe components (elbows, tees, reducers, caps) welded directly to piping systems to change direction, branch flow, or reduce pipe size. They’re essential in high-pressure, high-integrity systems like fire protection, HVAC, petrochemical, and industrial networks.

📍 Application Areas

Fire fighting systems (sprinkler, hydrant, riser lines)

HVAC systems (chilled water, heating loops)

Petrochemical and gas plants

Shipbuilding and offshore platforms

Industrial piping networks

🧩 Common Fitting Types

Elbows (90°, 45°) – change pipe direction

Tees – create branch connections

Reducers (concentric/eccentric) – transition between pipe sizes

Caps – seal pipe ends

Special fittings – custom shapes for specific layouts (e.g. scraper bar tees)

📊 General Technical Specifications

| Feature | Specification |

|---|---|

| Sizes | ½" to 48" |

| Wall thickness | SCH 10 to SCH 160 |

| Materials | Carbon steel (ASTM A234 WPB), stainless steel (ASTM A403), alloy steel |

| Manufacturing | Forged or welded |

| Connection type | Butt-weld (requires beveling and welding) |

| Surface finish | Black, galvanized, epoxy-coated |

| Temperature rating | Up to 600°C depending on material |

| Pressure rating | Up to 1000 PSI or more (varies by schedule) |

🏷️ Leading Brands in Egypt & MENA

TTU (Thailand) – widely used in fire fighting and HVAC

SHIELD (Europe/Asia) – UL/FM certified, premium quality

Both-Well (Taiwan) – high dimensional accuracy

BIS Pipe Fitting (Thailand) – cost-effective, reliable

Benkan (Japan) – top-tier for petrochemical and gas

Erne Fittings (Austria) – EN/DIN standard fittings

M.E.G.A (Italy) – specialized in stainless steel

✅ Certifications & Standards

UL Listed / FM Approved – required for fire protection systems

ANSI / ASME B16.9 – US standard for dimensions and tolerances

DIN / EN 10253 – European standards

JIS B2311 / B2312 – Japanese standards

ISO 9001 – quality management certification

PED / CE – pressure equipment directive for EU compliance

⚠️ Key Considerations

UL/FM approval is mandatory for fittings used in sprinkler and hydrant systems.

Welding quality and beveling must match pipe schedule and thickness.

Material traceability is critical in industrial and petrochemical applications.

Brand selection depends on project specs, budget, and required certifications.

🔧 Siam Butt‑Welding Fittings – Professional Overview

Definition

Siam fittings are forged or welded components designed to connect, branch, or change direction in pressurized piping systems. They are produced under strict dimensional tolerances and international standards, ensuring durability and safety.

Application Areas

Fire fighting systems – sprinkler, hydrant, and riser networks

HVAC installations – chilled water and heating loops

Petrochemical plants – high‑pressure fluid handling

Shipbuilding and construction – robust piping connections in harsh environments

Product Types

Elbows (90°, 45°) – change pipe direction

Tees – branch connections

Reducers – concentric/eccentric transitions between pipe diameters

Caps – pipe end closures

Special fittings – custom designs for specific layouts

Advantages

High dimensional accuracy – strict tolerances and wall thickness schedules

Wide size range – from ½” to 48”

Durable materials – carbon steel, stainless steel, alloy steel

Compliance with global standards – ANSI, DIN, JIS

Superior mechanical properties – corrosion resistance and pressure fatigue strength

📊 Technical Specifications

| Feature | Specification |

|---|---|

| Manufacturing | Forged or welded |

| Materials | Carbon steel, stainless steel, alloy steel |

| Standards | ANSI, DIN, JIS |

| Sizes | ½” to 48” |

| Thickness | SCH 10 to SCH 160 |

| Surface finish | Black, galvanized, epoxy-coated |

| Applications | Fire fighting, HVAC, petrochemical, shipbuilding |

Certifications

Manufactured to international dimensional standards (ANSI/DIN/JIS).

ISO 9001 quality management certified.

For fire protection projects, check if specific UL/FM approvals are required (Siam fittings are generally industrial grade, not UL/FM by default).

⚠️ Key note: Siam fittings are a cost‑effective alternative to premium UL/FM brands like SHIELD or Benkan. They are widely accepted in Egypt and MENA for HVAC and industrial projects, but in strict fire protection jobs (sprinklers/hydrants), consultants may demand UL/FM certified fittings.

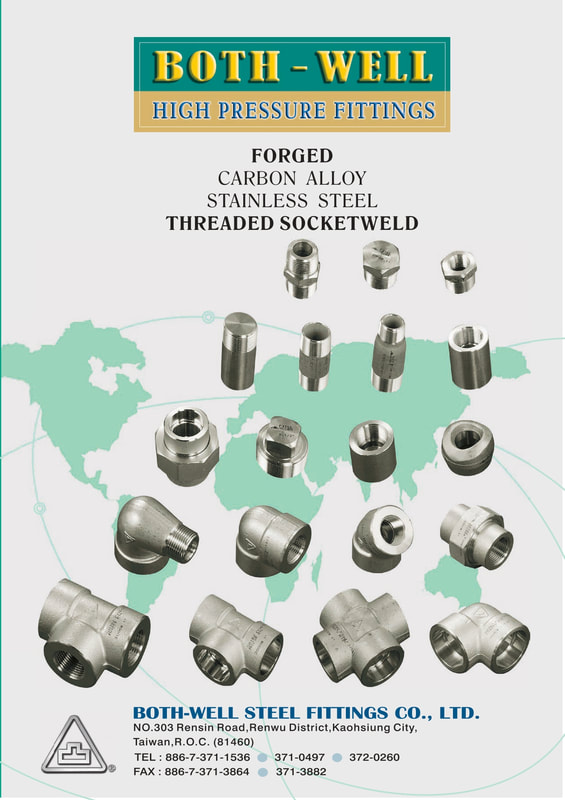

🔹 Bothwell Butt‑Welding Fittings – Professional Overview

Definition: Bothwell fittings are forged or welded pipe components manufactured in Taiwan, designed to connect, branch, or change direction in pressurized piping systems. They are recognized for high dimensional accuracy, strict quality control, and compliance with international standards.

Application Areas

Fire fighting systems – sprinkler and hydrant piping networks

HVAC installations – chilled water and heating systems

Petrochemical plants – handling high‑pressure fluids

Shipbuilding and offshore construction – durable piping connections in harsh environments

Product Types

Elbows (90°, 45°) – change pipe direction

Tees – branch connections

Reducers (concentric/eccentric) – transition between different pipe diameters

Caps – pipe end closure

Special fittings – custom designs for specific layouts

Advantages

High dimensional accuracy – precise tolerances and wall thickness schedules

Wide size range – from ½” to 48”

Durable materials – carbon steel, stainless steel, alloy steel

Compliance with global standards – ANSI, DIN, JIS

Superior mechanical properties – corrosion resistance and pressure fatigue strength

Trusted brand – Bothwell is well‑established in Asia and MENA markets

📊 Technical Specifications

| Feature | Specification |

|---|---|

| Manufacturing | Forged or welded |

| Materials | Carbon steel, stainless steel, alloy steel |

| Standards | ANSI, DIN, JIS |

| Sizes | ½” to 48” |

| Thickness | SCH 10 to SCH 160 |

| Surface finish | Black, galvanized, epoxy-coated |

| Applications | Fire fighting, HVAC, petrochemical, shipbuilding |

Certifications

Produced under ISO 9001 quality management system

Manufactured to ANSI/DIN/JIS dimensional standards

Generally not UL/FM certified by default, so for strict fire protection projects (sprinklers/hydrants) consultants may require UL/FM brands like SHIELD or Benkan

⚠️ Key note: Bothwell fittings are considered high‑precision industrial fittings. They are widely used in Egypt and MENA for HVAC and industrial projects, and often accepted in fire fighting systems where UL/FM certification is not mandatory.

🔹 BIS Pipe Fittings – Professional Overview

Definition: BIS Pipe Fittings are Thai‑manufactured butt‑welding fittings designed for use in pressurized piping systems. They are known for cost‑effective reliability, dimensional accuracy, and compliance with international standards. BIS has a strong presence in fire fighting, HVAC, and industrial projects across Asia and the Middle East.

Application Areas

Fire fighting systems – sprinkler and hydrant piping networks

HVAC installations – chilled water and heating systems

Petrochemical plants – handling high‑pressure fluids

Shipbuilding and construction – durable piping connections in harsh environments

Product Types

Elbows (90°, 45°) – change pipe direction

Tees – branch connections

Reducers (concentric/eccentric) – transition between different pipe diameters

Caps – pipe end closure

Special fittings – custom designs for specific layouts

Advantages

Reliable quality at competitive cost – strong value compared to premium brands

Wide size range – from ½” to 48”

Durable materials – carbon steel, stainless steel, alloy steel

Compliance with global standards – ANSI, DIN, JIS

Good mechanical properties – corrosion resistance and pressure fatigue strength

Widely available – strong distribution network in Egypt and MENA

📊 Technical Specifications

| Feature | Specification |

|---|---|

| Manufacturing | Forged or welded |

| Materials | Carbon steel, stainless steel, alloy steel |

| Standards | ANSI, DIN, JIS |

| Sizes | ½” to 48” |

| Thickness | SCH 10 to SCH 160 |

| Surface finish | Black, galvanized, epoxy-coated |

| Applications | Fire fighting, HVAC, petrochemical, shipbuilding |

Certifications

Manufactured to ANSI/DIN/JIS dimensional standards

ISO 9001 certified for quality management

Generally not UL/FM certified by default, so for strict fire protection projects (sprinklers/hydrants) consultants may require UL/FM brands like SHIELD or Benkan

⚠️ Key note: BIS fittings are considered a cost‑effective, reliable option. They are widely used in Egypt and MENA for HVAC and industrial projects, and often accepted in fire fighting systems where UL/FM certification is not mandatory.